317 and 317L stainless steel pipes are high-performance alloys that offer superior corrosion resistance, high strength, and excellent durability in harsh environments. Their resistance to pitting, crevice corrosion, and general corrosion makes them ideal for use in industries such as chemical processing, oil and gas, marine, and pulp and paper. The key difference between 317 and 317L lies in their carbon content, with 317L offering improved weldability and reduced risk of sensitization. Both alloys provide excellent mechanical properties and are suitable for use in high-pressure and high-temperature applications.

October, 2024 » Stainless Steel & Alloy Steel Pipes | 2PE 3PE coated pipe | Pipe Fittings - Pipeline Technology R&D Factory

Estimating the lifespan of galvanized steel and stainless steel pipes involves a comprehensive understanding of material properties, environmental conditions, and operational stresses. By employing a combination of empirical, mathematical, and testing methodologies, stakeholders can make informed decisions about material selection

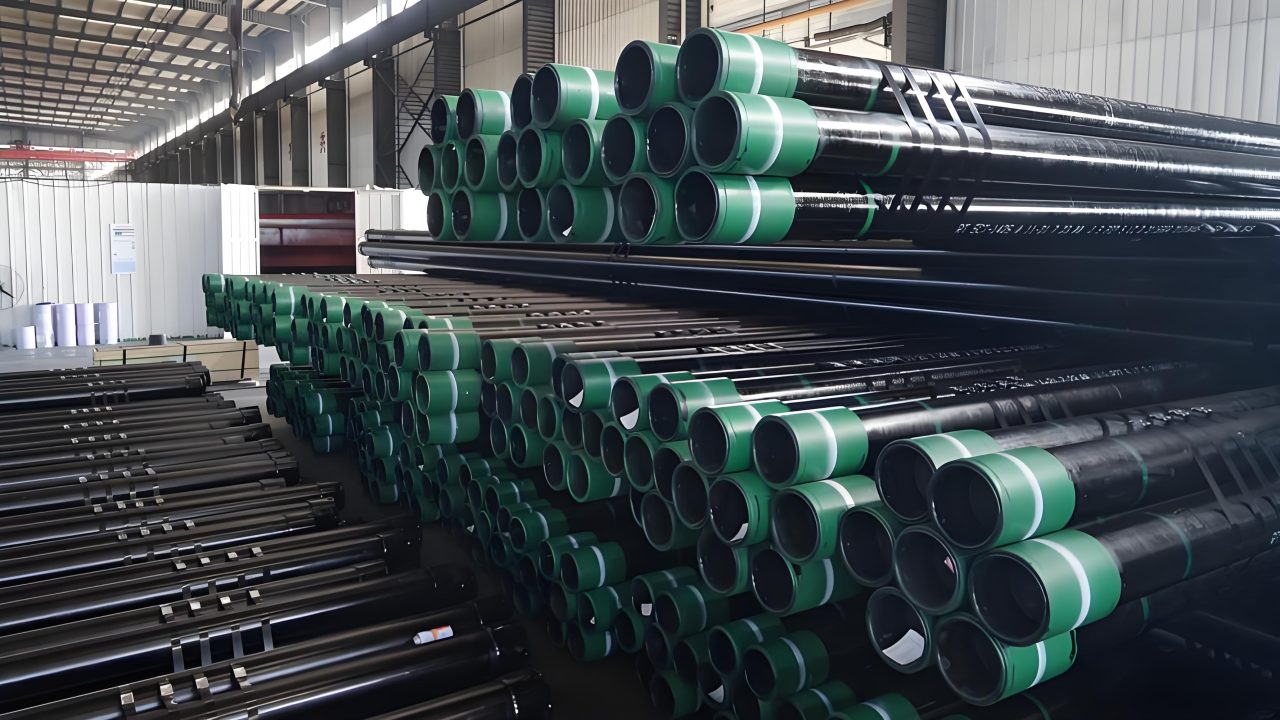

Conclusion The rotation speed of steel pipes against steel casings in petroleum drilling significantly influences the abrasive–erosive–corrosive wear processes. Understanding these effects allows for better material selection, operational strategies, and design improvements to extend the life of drilling components. Ongoing research and technological advancements continue to improve our ability to predict and mitigate wear, ensuring safer and more efficient drilling operations. This comprehensive exploration highlights the critical role rotation speed plays in wear processes, providing a foundation for further study and innovation in the field.

This study has provided a comprehensive analysis of the effects of tube bending, heat treatment, and loading paths on the hydroforming process for automobile intercooler pipes. The combination of experimental and numerical investigations has yielded valuable insights into optimizing the hydroforming process, leading to improved mechanical properties and dimensional accuracy of the final components.

This study has provided valuable insights into the impact of steel pipeline installation and external loads on buried steel pipe responses. The integration of experimental and numerical investigations has enhanced our understanding of the mechanical behavior of these pipes under various conditions. Key findings include the significant influence of installation methods on pipe deformation and the critical role of external loads in determining structural integrity.

A249 316/316L stainless Steel Heat Exchanger Tube offer a combination of excellent corrosion resistance, mechanical strength, and versatility, making them suitable for a wide range of applications across various industries. Understanding their composition, properties, and manufacturing processes is essential for selecting the right material for specific

Inconel 718 alloy steel seamless tubing, designated as UNS N07718, offers a combination of high-temperature resistance, corrosion resistance, and mechanical strength, making it suitable for demanding applications in aerospace, oil and gas, and power generation. The manufacturing processes, from melting to quality control, ensure that these tubes meet the stringent requirements of various industries. As technology advances and the demand for durable materials grows, Inconel 718 seamless tubing is poised to play an increasingly important role in the future of industrial engineering.

600 Nickel Alloy tubes, designated as UNS N06600 and WNR 2.4816, offer a combination of high-temperature resistance, corrosion resistance, and mechanical strength, making them suitable for demanding applications in chemical processing, aerospace, and power generation. The manufacturing processes, from melting to quality control, ensure that these tubes meet the stringent requirements of various industries. As technology advances and the demand for durable materials grows, 600 Nickel Alloy tubes are poised to play an increasingly important role in the future of industrial engineering.

Headquarters

We are everywhere