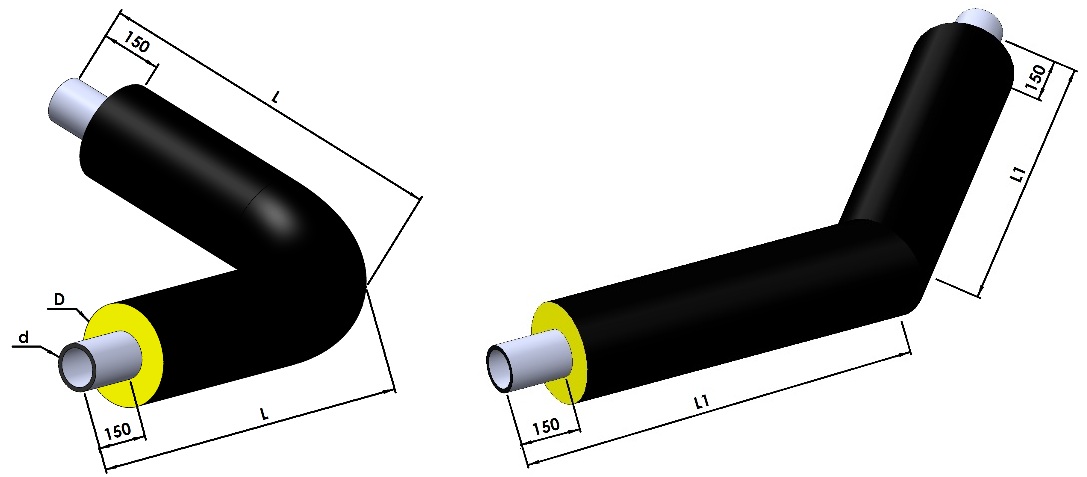

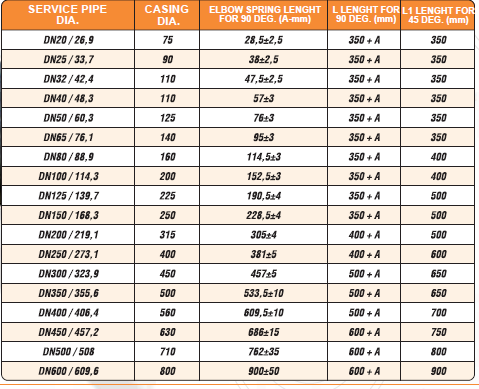

Pre-Insulated steel elbow

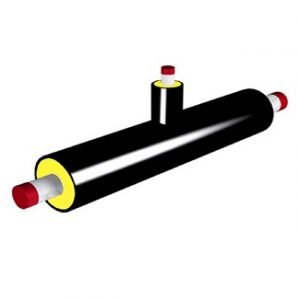

A HDPE (High-Density Polyethylene) pre-insulated steel elbow is a crucial component used in pipe systems to change the direction of the pipeline while maintaining the system’s thermal insulation properties.

This fitting is composed of three main parts:

Steel Elbow: The steel elbow is the innermost component that facilitates the change in direction of the flow within the pipeline. It is usually made from carbon steel or stainless steel and is designed to resist the temperature and pressure of the fluid being transported.

Insulation Layer: The steel elbow is surrounded by an insulation layer, often made from polyurethane foam. This layer provides thermal insulation, reducing heat loss (or gain, in the case of cooling systems), thereby enhancing the energy efficiency of the system.

Outer Casing: The outermost layer is typically a casing made from High-Density Polyethylene (HDPE). This casing provides mechanical protection for the steel elbow and the insulation layer. It also serves as a barrier against moisture and other environmental conditions, ensuring the longevity and performance of the system.

The design and materials used for HDPE pre-insulated steel elbow may vary based on specific application requirements, including the operating temperature and pressure, the type of fluid being transported, and environmental conditions. As with all components in a piping system, a pre-insulated steel elbow should be installed and maintained according to the manufacturer’s instructions.

.

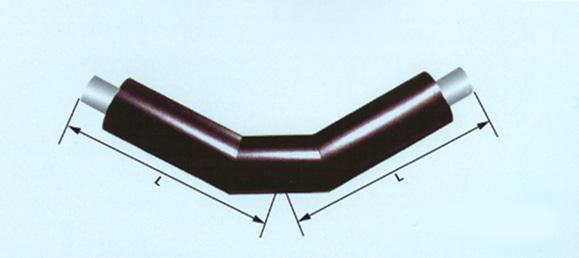

| 45°insulation elbow | |||||

| Norminal diameter (mm) | L (mm) | ||||

| 1.5DN | 2.5DN | 3DN | 3.5DN | 4DN | |

| 20 | 410 | 520 | 525 | 530 | 535 |

| 25 | 415 | 525 | 530 | 535 | 540 |

| 32 | 420 | 530 | 540 | 545 | 555 |

| 40 | 425 | 540 | 550 | 560 | 565 |

| 50 | 430 | 550 | 560 | 570 | 585 |

| 70 | 445 | 570 | 590 | 600 | 615 |

| 80 | 450 | 580 | 600 | 615 | 635 |

| 100 | 470 | 605 | 625 | 645 | 665 |

| 125 | 700 | 630 | 655 | 680 | 710 |

| 150 | 770 | 655 | 685 | 715 | 750 |

| 200 | 950 | 810 | 850 | 890 | 930 |

| 250 | 950 | 960 | 910 | 960 | 1015 |

| 300 | 950 | 910 | 975 | 1035 | 1095 |

| 350 | 1200 | 960 | 1035 | 1110 | 1180 |

| 400 | 1200 | 1015 | 1095 | 1180 | 1265 |

| 450 | 1200 | 1265 | 1360 | 1450 | 1545 |

| 500 | 1200 | 1320 | 1420 | 1525 | 1630 |

| 600 | 1200 | 1420 | 1545 | 1670 | 1795 |

| 700 | 1300 | 1525 | 1670 | 1815 | 1960 |

| 800 | 1400 | 1630 | 1795 | 1960 | 2125 |

| 900 | 1400 | 1930 | 2200 | 2305 | 2490 |

| 1000 | 1400 | 2035 | 2245 | 2450 | 2655 |

| 1200 | 1500 | 2500 | 2800 | 3100 | 3400 |

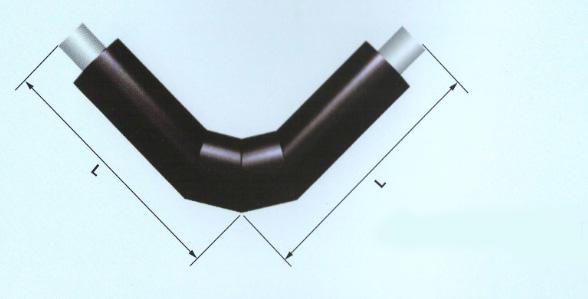

| 90° insulation elbow | |||||

| Norminal diameter (mm) | L (mm) | ||||

| 1.5DN | 2.5DN | 3DN | 3.5DN | 4DN | |

| 20 | 430 | 550 | 525 | 530 | 535 |

| 25 | 440 | 560 | 530 | 535 | 540 |

| 32 | 450 | 580 | 540 | 545 | 555 |

| 40 | 460 | 600 | 550 | 560 | 565 |

| 50 | 475 | 625 | 560 | 570 | 585 |

| 70 | 505 | 675 | 590 | 600 | 615 |

| 80 | 520 | 700 | 600 | 615 | 635 |

| 100 | 550 | 750 | 625 | 645 | 665 |

| 125 | 700 | 810 | 655 | 680 | 710 |

| 150 | 770 | 875 | 685 | 715 | 750 |

| 200 | 950 | 1100 | 850 | 890 | 930 |

| 250 | 1200 | 1225 | 910 | 960 | 1015 |

| 300 | 1200 | 1350 | 975 | 1035 | 1095 |

| 350 | 1350 | 1475 | 1035 | 1110 | 1180 |

| 400 | 1350 | 1600 | 1095 | 1180 | 1265 |

| 450 | 1425 | 1925 | 1360 | 1450 | 1545 |

| 500 | 1500 | 2050 | 1420 | 1525 | 1630 |

| 600 | 1650 | 2300 | 1545 | 1670 | 1795 |

| 700 | 1850 | 2550 | 1670 | 1815 | 1960 |

| 800 | 2100 | 2800 | 1795 | 1960 | 2125 |

| 900 | 2250 | 3250 | 2200 | 2305 | 2490 |

| 1000 | 2400 | 3500 | 2245 | 2450 | 2655 |

| 1200 | 2700 | 4000 | 2800 | 3100 | 3400 |

2 comments

Pingback: Hot Induction Bend pipes : A Comprehensive Guide » Stainless Steel & Alloy Steel Pipes | 2PE 3PE coated pipe | Pipe Fittings - Pipeline Technology R&D Factory

Ronsun2023

2025年3月28日 at pm9:48

Induction bending is a very efficient and precise bending technique using heat in order to bend tubes, pipes and sections. It takes over where cold bending methods meet their limitations. The combination of speed, local heat and cooling allows for bending even bigger profiles.