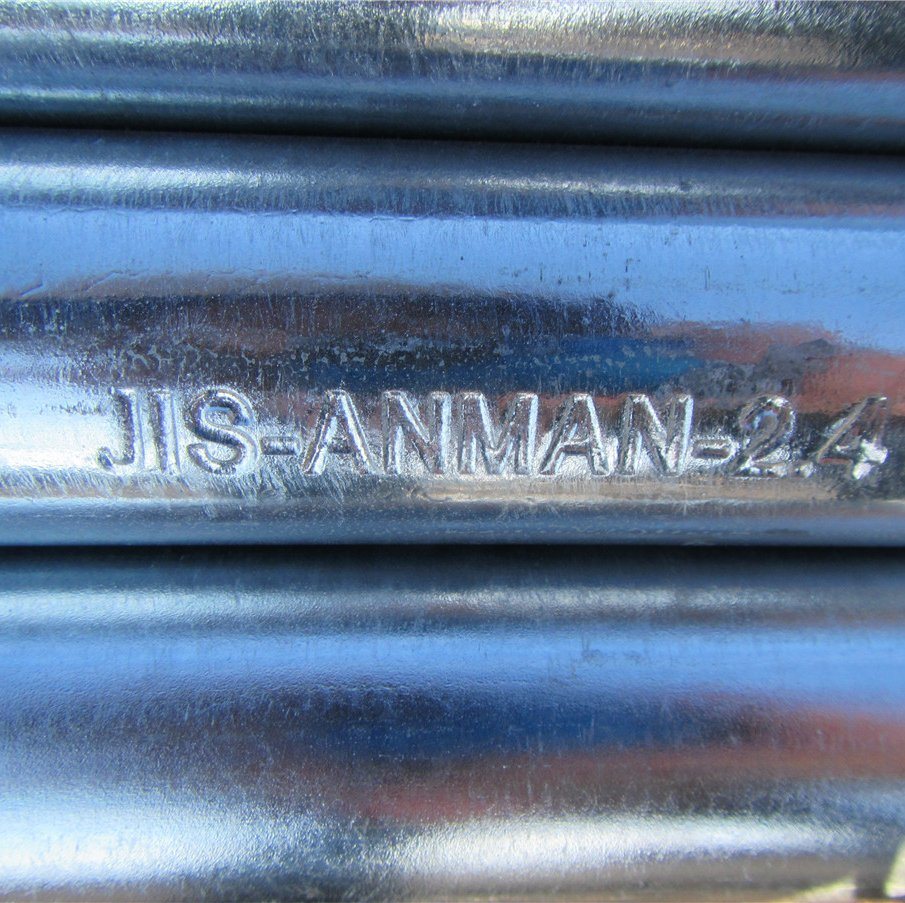

Hot Dipped Galvanized Steel Scaffold Pipe

pre-galvanized components are usually only immersed in the galvanizing bath for a very short time, resulting in a relatively thin coating. The thicker zinc coating produced by hot dip galvanization offers improved rust and corrosion protection versus pre-galvanization.

What are the advantages of using a double-layer FBE coating system compared to a single-layer coating?

A hard, mechanically strong top coating for all fusion bonded epoxy pipeline corrosion protection coatings. It is applied to the base coating to form a tough outer layer that is resitant to gouge, impact, abrasion and penetration. abter steel is specifially designed to protect the primary corrosion coating from damage during pipeline directional drilling applications, bored, river crossing and installation in rough terrain.

Zinc Coated Galvanized Steel Pipe

Galvanized pipes have a wide range of uses. In addition to oil and other low-pressure fluid pipelines, it is also used as oil well pipes in the petroleum industry, especially in offshore oil fields, oil heaters in chemical coking equipment, coal distillation, and oil washing converter pipes, bridges, etc. Pipe pile, mining tunnel support frame with pipe, etc. Developed countries in the world started to develop new pipes and continuously banned galvanized pipes.

Connecting Stainless Steel Pipe to Carbon Steel Pipe Fittings

In industrial and residential applications, it is frequently necessary to join different types of metals. These connections can be between stainless steel and carbon steel, two of the most commonly used materials in piping systems. This article will walk you through the process of connecting stainless steel pipe to carbon steel pipe fittings, the challenges involved, and how to overcome them.

Dimensions & Weight of Welded and Seamless Steel Pipe ASME B 36.10 / B 36.19

Based on the information provided, the ASME B 36.10 and B 36.19 standards define the dimensions and weight of welded and seamless steel pipes. These standards provide guidelines for the manufacturing and installation of steel pipes in various industries, including oil and gas, petrochemical, and power generation. ASME B 36.10 specifies the dimensions and weights of welded and seamless wrought steel pipes. It covers pipes ranging from NPS 1/8 (DN 6) through NPS 80 (DN 2000) and includes various wall thicknesses and schedules. The dimensions covered include outside diameter, wall thickness, and weight per unit length.